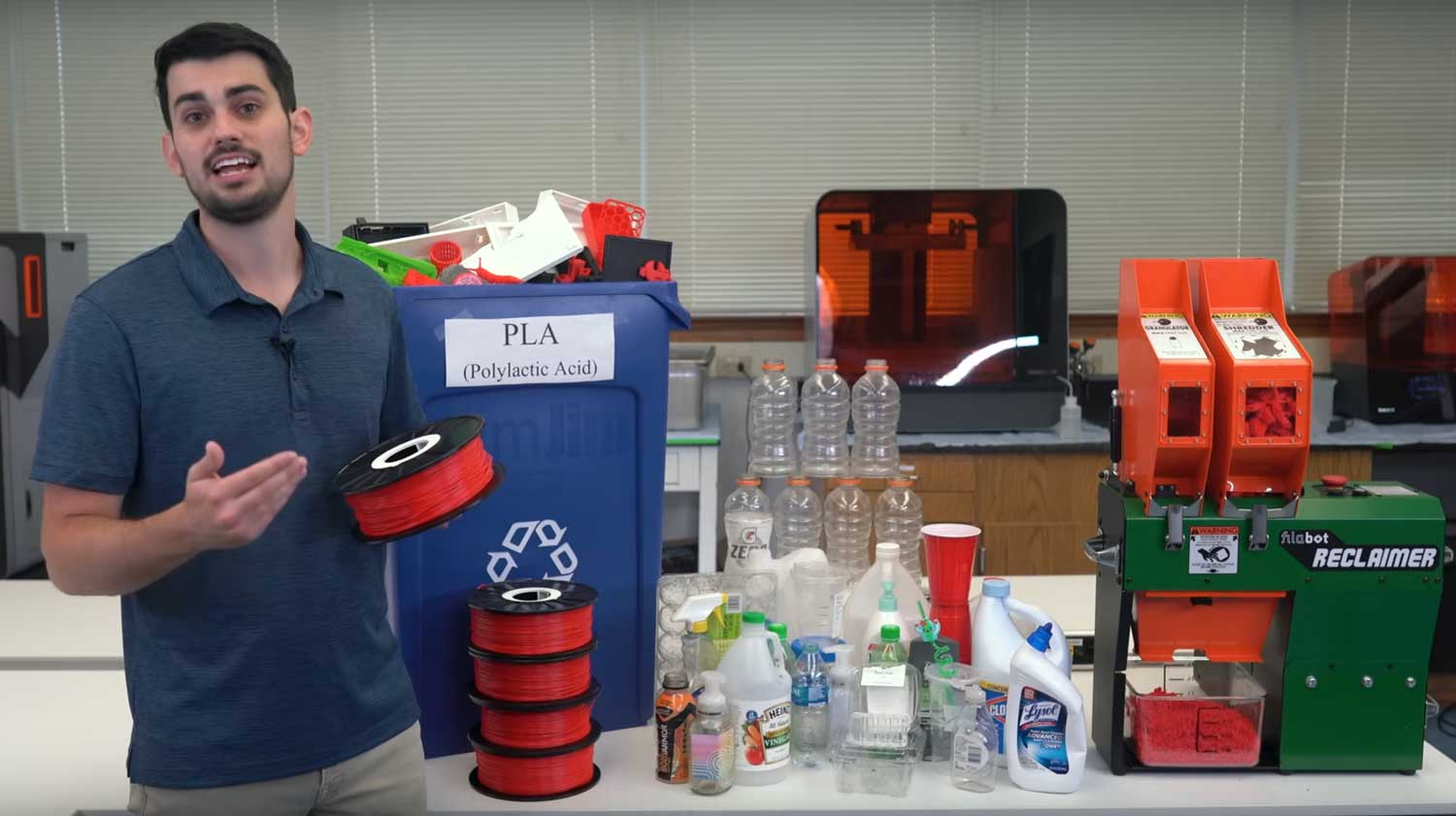

In a new video on YouTube, it appears doctor. D-Flo Step by step on how to recycle unused 3D prints, misprints and household plastics into 3D printer filament.

Production waste can be recycled using shredders, extruders and pelletizing machines. However, the process is very complicated: for 1 kg of thread, Dr. D-Flo is about 2.5 hours. Recycling household plastics such as plastic bottles is more difficult.

According to Dr. D-Flo, unwanted 3D prints made from PLA plastic are particularly suitable for recycling. For PET bottles, the material must first be shredded and extruded several times to produce a usable filament. The irregular shape of plastic fragments in particular makes further processing difficult.

Despite the efforts, recycling is worth it for environmental reasons. doctor. D-Flo explains in his video that special industrial facilities will be necessary to make household plastics recycling truly effective. However, his experience shows that 3D printing waste can be almost completely converted into new filament with very little time.

Don’t miss any other news!

We deliver the most important news and information on the topic of 3D printing to your inbox every week for free. Log in here.

“Total coffee aficionado. Travel buff. Music ninja. Bacon nerd. Beeraholic.”

More Stories

GenAI in everyday work – Top management is moving forward with AI, employees are hesitant » Leadersnet

Foreign Exchange: Euro rises against the dollar

Lufthansa Group: Austrian Airlines, the Boeing 737 MAX and the cargo problem