Toyota and Redwood Materials already know each other: supplying battery components made from recycled materials is the focus of an expanded cooperation agreement just concluded by the two companies, which builds on the announced collaboration in 2022 to collect and recycle used batteries from Toyota. Hybrid cars. The aim is to create a circular, domestic supply chain for the production of batteries for Toyota’s electric and hybrid cars.

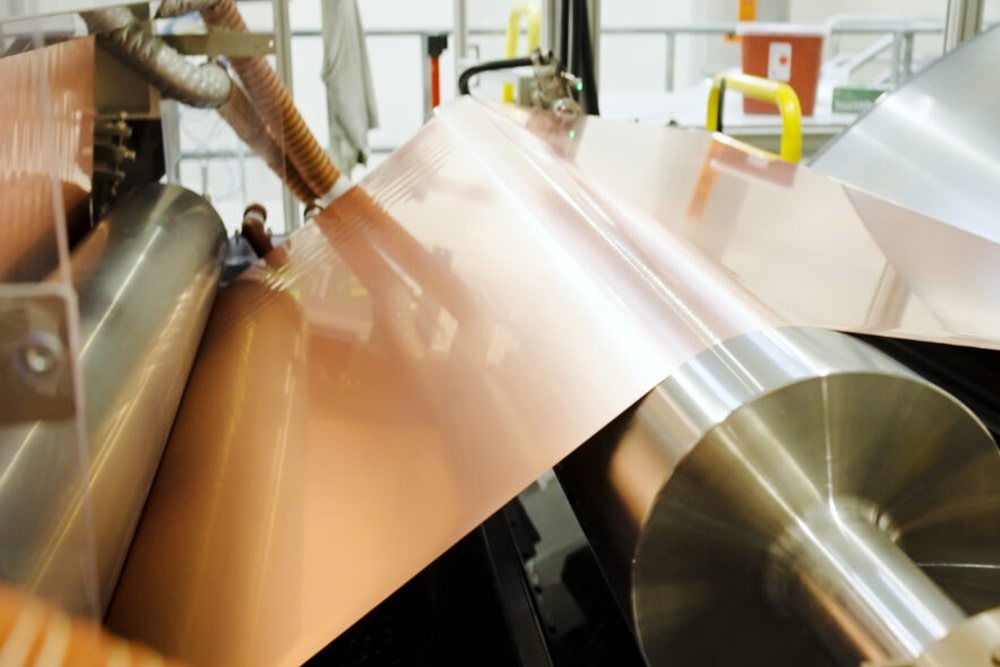

Redwood says it is targeting a recycled content of at least 20 percent of cathode material for Toyota for nickel and lithium and 50 percent for cobalt. The foil for the anodes must contain 100 percent recycled copper. Absolute supply quantities or supply periods are not specified. However, both sides are talking about a “long-term deal”.

“Today, by working with us, Toyota is taking an important step toward a sustainable future,” said Cal Langton, chief commercial officer of Redwood Materials. “Not only do they ensure responsible lifecycle management of their electric vehicles, but they also plan to develop the next generation of electric vehicles using sustainable and locally produced battery components.”

Christopher Yang, Group Vice President, Business Development, Toyota Motor North America commented, “Our recycling efforts and accelerating domestic parts sourcing move us closer to our goal of creating a closed battery ecosystem, which will become increasingly important in more and more vehicles. The batteries are on the roads of North America.

Toyota recently announced an investment of $8 billion to $13.9 billion in its battery plant in North Carolina. This equates to around 13.16 billion euros. The plant is scheduled to be operational by 2025.

The money will be used to build eight additional production lines for BEV and PHEV batteries. According to Toyota, there are still only four planned production lines for batteries for hybrid vehicles. By 2030, Toyota wants to reach more than 30 GWh per year of battery production in North Carolina.

“With the announcement, Toyota North Carolina solidifies its position as the center of lithium-ion battery production in North America. In total, the campus will cover seven million square meters, the equivalent of 121 football fields,” the carmaker wrote in a press release earlier this month.

It was recently announced that Toyota Motor North America Cathode materials from LG Chem to the plant in North Carolina. Deliveries are expected to begin in 2025. In addition to self-manufactured batteries, Toyota will also purchase batteries from LGES. Beginning in 2025, LGES is expected to annually supply battery modules with a total capacity of 20 gigawatt hours, containing NCMA bi cells with high nickel content, that Toyota will install in new electric cars manufactured in the United States. Toyota will produce its first BEV model in the US starting in 2025: an SUV with three rows of seats, rolling off the assembly line in Kentucky.

“Amateur coffee fan. Travel guru. Subtly charming zombie maven. Incurable reader. Web fanatic.”

More Stories

Nicolas Loufrani: Young Londoners Design Afro Hair Emojis

US Election: Trump Vs. Harris – 2024 poll numbers in America

Börse Express – USA: Retail sales rise unexpectedly