Creators have always realized unusual ideas using 3D printing and modern technology. YouTuber Chris Borg built a small but powerful 3D-printed lathe and documented the construction process.

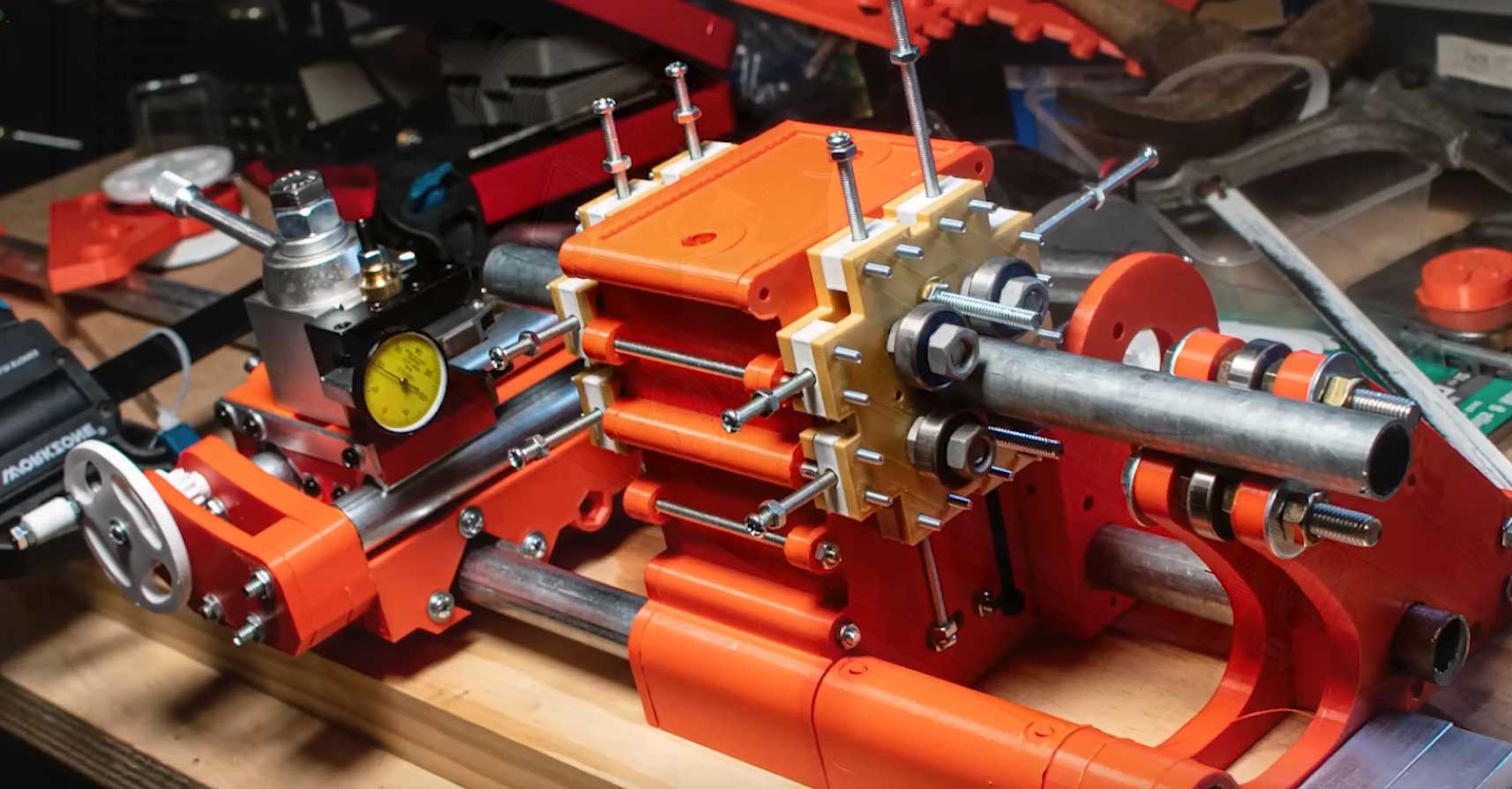

In his video, Borg takes you through the iterative process – from flawed prototypes to the final version of his homemade lathe. The core is a 3D printed shell held together by poured concrete. The motor drive, bearings and guides are completed from the hardware store and inexpensive parts.

The innovative design impresses with its slim design without a traditional cross-axle. Instead, the turning tool is driven directly. Despite the simple design, various turning and drilling works can be performed.

In a series of demonstrations, Borg demonstrated the versatility of the lathe – from making simple metal parts from aluminum bars to decorative wood parts. Lathe operations are incredibly precise thanks to manual tool guidance.

“It is not intended to compete with professional lathes, but rather to be an inexpensive alternative for makers and hobbyists,” Borg emphasizes. If you build it yourself, a 3D printing lathe costs between $100 and $200 max – depending on how much you make yourself.

Many useful modifications are planned such as an adjustable tool holder or copy copier. It also makes the final version available for free on Thingiverse.

Don't miss any other news!

We deliver the most important news and information on the topic of 3D printing to your inbox every week for free. Log in here. We are there too LinkedIn To exist. You can us Follow here!

“Social media evangelist. Baconaholic. Devoted reader. Twitter scholar. Avid coffee trailblazer.”

More Stories

Longest jets in the universe discovered – giant particle streams as long as 140 Milky Way galaxies in a row

New method reveals 307 supernova remnants

Snapchat is upping the ante on augmented reality glasses