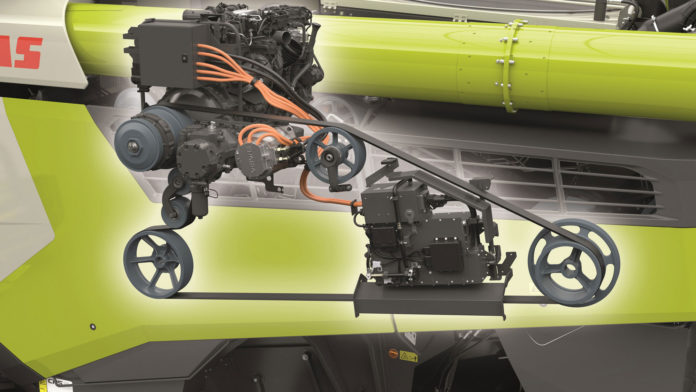

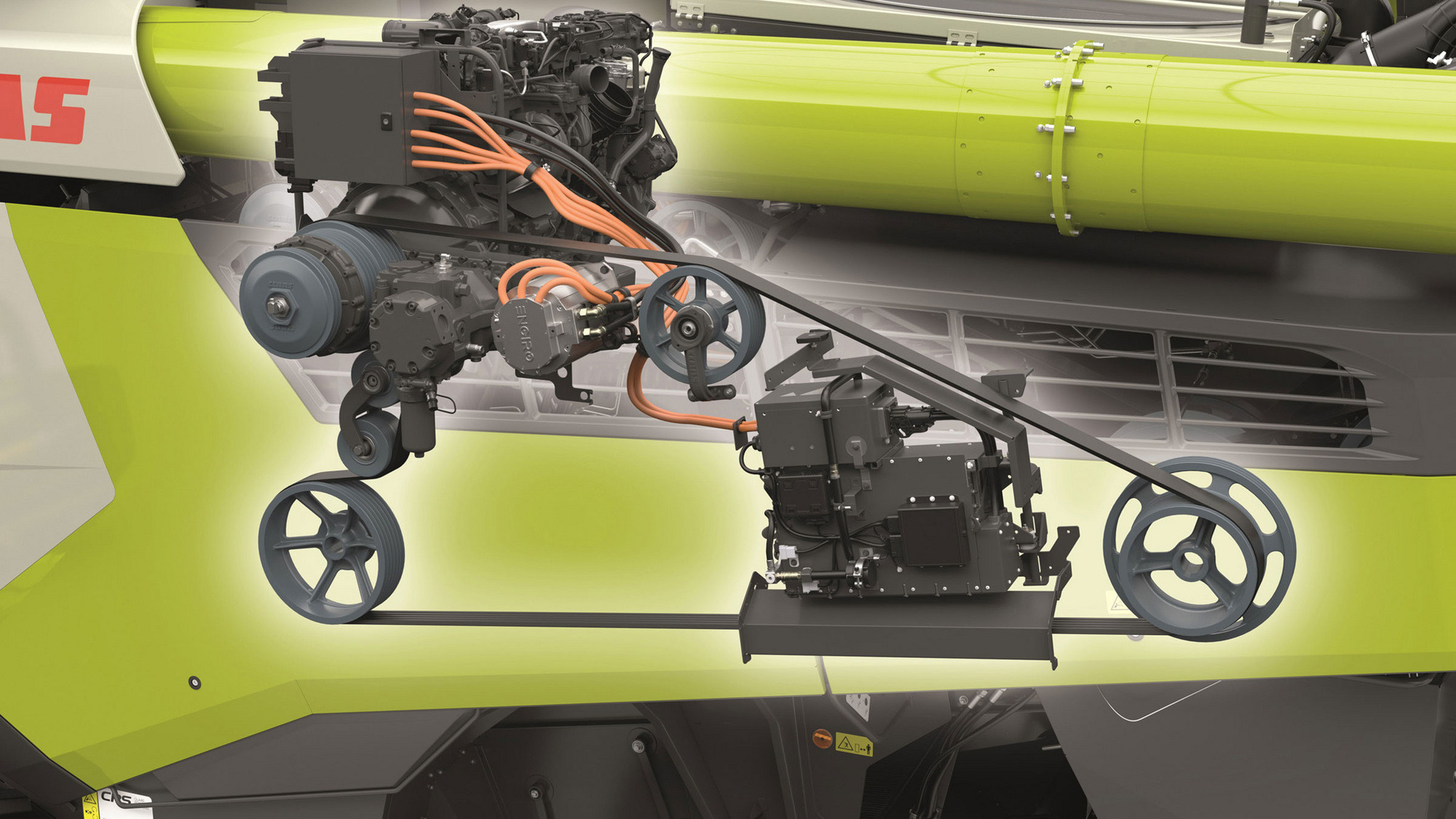

Claas presents a concept of combine harvesters based on a hybrid drive for the first time at Agritechnica.

MHarvesters often have to deal with heterogeneous operating conditions when harvesting. Uneven grain and straw yields, mixed growth or uneven terrain require engines and units to constantly adapt. Especially from the point of view of efficiency, but also with regard to optimal separation and cleaning performance, continuous high use of the motor without large fluctuations in speed and a more uniform crop flow are desirable. However, this is difficult to achieve due to population heterogeneity.

By using a partially electrified engine in the combine, load peaks can be mitigated and efficiency can be greatly increased. Under simple harvesting conditions, engine power not required to drive the harvester is converted into electrical power via a generator and stored in the battery. In difficult harvesting conditions, for example in field areas with high productivity, or when refueling while driving, the stored electrical energy from the battery automatically supports the mechanical drive with an electric motor, thus replacing the classic “boost” generated via the engine map. “Load peaks can be overcome within several seconds, and thanks to the automatic load distribution, the harvester can be constantly operated at its best performance,” explain the experts from Caas.

According to the company, this concept allows the use of a smaller, less powerful combustion engine of about 400 kW, which can be operated in the low speed range at 1,600 instead of 1,800 rpm thanks to an additional 40 kW and 3 kWh electric motor. Battery with 48V inverter. “In practical tests, fuel consumption was reduced by up to 10 percent thanks to the partially electrified hybrid concept,” says Klass. It is also confirmed that electric drive occurs in the low voltage range (<60 V contact voltage). Compared to high-voltage drives, fewer complex safety precautions are needed.

– Advertising –

“Total coffee aficionado. Travel buff. Music ninja. Bacon nerd. Beeraholic.”

More Stories

Wealthy families take more risks when it comes to money.

Salesforce and NVIDIA Form Strategic Collaboration to Drive AI Customer Innovation

Changing banks causes problems for customers